Mining Solutions Patented 2 Piece Dynamic Classifier Blade ...

This SAS Two Piece Dynamic Classifier Blade System was engineered to be easy and safe to install and will outlast the original blades by 2 or 3 times.

WhatsApp)

WhatsApp)

This SAS Two Piece Dynamic Classifier Blade System was engineered to be easy and safe to install and will outlast the original blades by 2 or 3 times.

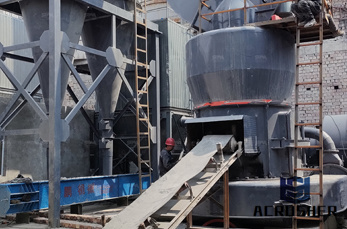

Mining machinery equipment, mill supplier, new crusher. Hammer Crusher Hammer crusher dynamic classifier for coal mill; stone crusher in nangal zone rajasthan; emo 2012 grinding machine; manufacture of juicer grinder . Hammer crusher Spiral classifier VSI crusher. Spiral Classifier, Grinding Mill, Crusher Machine, SandSpiral classifier is a ...

SELVN HAMMER MILL SCREEN PULVERIZER YouTube. Dec 25, 2015 . We have heavy duty hammer mill screen pulverizer with blower,cyclone,dust collector attached starts from 20 hp to 125hp to meet higher out. Contact US GCS 1500 Direct Drive Pulverizing Mill Unit Global Cutting Systems. Classifier and Cyclone Work Platforms provide access to level related .

Rugged and durable, Classifier Milling System''s superior hammer mill grinder is preferred by thousands of chemical and manufacturing plants around the world. With thousands of successful installations, these mills continue to perform in a superior manner. To put it simply, you can count on CMS''s hammer mill grinder to last you a very long time.

The Mill ROTODUE 4C is suitable to produce air classified powders with granulometry in the range 0 to 100÷300 micron, with d50=in the range 10÷40 micron. Product fineness is easily adjustable by varying the speed of the dynamic air classifier, with speed controlled by Inverter.

These features allow the classifier to make precise separations at very small micron sizes. We also have installed a sieve mill, which is similar to a hammer mill except it uses a screen to determine particle size. Within the sieve mill, the grinding is achieved by the material .

The ConJet ® highdensity bed jet mill is a spiral jet mill combined with a patented dynamic air classifier. This classifier enables the ConJet ® to achieve highest finenesses independent of the product load, and therefore also highest throughput rates. Applicable for finenesses from to 70 µm (d97). Machine sizes available for grinding air volumes from approx. 50 to 2,400 Nm³/h.

The CSM classifier mill combines a mechanical impact mill with an integrated dynamic air classifier. The grinding is performed between a peripheral grinding track and the rotating beater gear. Due to the integrated classifier wheel, grain sizes free of coarse particles can be achieved without the disadvantages of an external grinding and ...

The air classifier mill combines a mechanical impact mill with an integrated dynamic air classifier. It is an air swept mechanical impact mill designed to grind materials down to 10 microns. The air classifier mill uses air to carry the product through the fine grinding milling machine and classifying process.

Jul 07, 2017· Top five productspecific milling technologies used in industrial applications today. ... ACM is a general term for many types of impact mills that also incorporate dynamic classifier technology as part of the mill design. ACMs are the most widely used milling technology in the powderprocessing industry today for the general size reduction of ...

Hosokawa Micron Powder Systems Full Catalog MikroPulverizer® Hammer Mill. Item #: MP44 MikroPulverizer® Hammer Mill Description. Images. Specifications; Capacity: ... The basic concept of these mills is the impact size reduction that is coupled with an internal dynamic classifier which will control the outlet (product) particle size via ...

The SAS Adjustable High Spin Static Classifier Retrofit is a proven and reasonable alternative to making the substantial capital commitment required for Dynamic Classifiers. SAS customers have achieved 6% to 15% capacity improvements, while concurrently reaching % thru 50 mesh and % thru 200 mesh fineness levels – grinding at 42 HGI coal.

Dec 07, 2011· Dynamic Classifier Mill (DCM) plant atritorlimited. ... LOESCHE LSKS Dynamic Classifier Duration: 1 ... Discrete element modeling of particle breakage inside a hammer mill .

Nov 23, 2015· Dynamic classifier has ability to produce micron fine pulverized coal having narrow particle size distribution. Just like vertical roller mill, bowl mill is also a medium speed device used for crushing coal. It comes into two types deep bowl mill and shallow bowl mill. High Speed Pulverizer. Attrition mill, beater wheel mill, hammer mill, and ...

The basic design of these mills is the impact size reduction that is coupled with an internal dynamic classifier which controls the outlet (product) particle size via recirculating the coarse particles back into the grinding zone. There are seven main factors which determine particle size distribution for the Mikro ACM® Air Classifying Mill.

With adequate mill grinding capacity, a vertical mill equipped with a static classifier is capable of producing a coal fineness up to % or higher <50 mesh and 80% or higher <200 mesh, while one equipped with a dynamic classifier produces coal fineness levels of .

feeding (, making metering into the mill difficult), grinding (, plugging the hammer mill screen or blocking the air classifier of a jet mill), and collection (, plugging the bag filters). There are two ways to grind sticky materials. The first solution is to dry the material prior to grinding, or dry and

Welcome to Classifier Milling Systems. Classifier mills are particularly complex structures. At Classifier Milling Systems, our selection of flexible powder processing equipment and expertise regarding classifier mills is incomparable. Our team''s commitment to the customer sets a higher standard in the industry.

HAMMER MILL Highperformance grinding for many applications We are crushing it – no matter what it may be A COMPLETE SOLUTION The correct combination of hammer mill type, screens, hammers, speed, feeding system, and air flow through the hammer mill ensures the required grinding results and creates optimum conditions for

Prater''s Mega Mill Hammer Mill was manufactured with the intent of bridging the tough gap between hammer mills and fine grinders. Our Mega Mill provides uniform grinding with less heat buildup and a unique bearing and shaft arrangement that creates a smoother, quieter .

May 24, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

The hammer mill uses an internal screen mounted below the grinding rotor to control particle top size. If finer or narrower particle size distributions are desired, an external dynamic classifier can be installed downstream from the mill to separate the coarse fraction or return oversize materials to the hammer mill.

Air Classifier Mill. Operating in the medium to fine particle size reduction range the Mikro ACM delivers guaranteed, accurate particle size because of the highly efficient, variable speed dynamic integral air classifier and achieves a steep particle size distribution with minimum ultra fines.

Aug 15, 2013· Hosokawa Mikro ACM Easy Access Air Classifying Mill ... impact mills have a dynamic air classifier designed to grind an extensive range of materials down to a D97 = 20 µm. ... coupled with an ...

WhatsApp)

WhatsApp)