Used Processplants For Sale

USED 300500 TPD Modular Gold Plant including 6'' x 8'' Ball Mill, Falcon Concentrators, Screens, Pumps, Conveyors, Cyclones and More. Inventory ID: 18CJD01.

WhatsApp)

WhatsApp)

USED 300500 TPD Modular Gold Plant including 6'' x 8'' Ball Mill, Falcon Concentrators, Screens, Pumps, Conveyors, Cyclones and More. Inventory ID: 18CJD01.

Small Gold Processing Plant Mineral Processing Metallurgy. The problem a Small Gold Processing Plant can solve is for the need to to provide a small, relatively simple and inexpensive gold mill that will operate at a reasonable profit with a minimum of supervision.

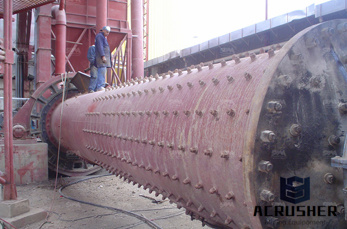

Ball Mill In A Mine Plant oscardeisaporiit use of ball mill in mine plant Mineral Processing EPC Gold Mill Plant About 59% of these are mine mill, 1% are other machinery industry equipment A wide variety of gold mill plant options are available to you, such as ball mill....

Resources Modular Gold Plants (MGP) are complete turnkey modular gold plants designed for the 500 to 2000 ton per day producer. Permitting requirements and land disturbance are minimized as a result of the inherent environmentally friendly processing technology and compact footprint of the Modular Gold Plants.

A stamp mill (or stamp battery or stamping mill) is a type of mill machine that crushes material by pounding rather than grinding, either for further processing or for extraction of metallic material down is a type of unit operation

A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved. Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver. This process removes 93% of the gold and 70% of the silver.

used gold rod mill plant nz · A Verified CN Gold Supplier on used gold rod mill plant nz . ball mill machinery liner plate bolts crusher jaw plate hotmail, gmail yoo,id,lk,uk,us,ua,,au pe 250 x 400 jaw crusher widely used in chemical industry Stone Production Line,stone crusher plant,stone crushing plant.

Dec 07, 2016· ''Scruffy'' tells Tim Glidewell about his wet processing plant. Skip navigation ... Gold mine in Western Australia Wet Production plant ... UMP 4 ton per hour prospecting and placer mining gold ...

gold mining plant suppliers sudan gold mining tin mining plant suppliers. sudan gold mining tin mining plant suppliers Chrome Ore Sudan, Chrome Ore Sudan Suppliers and and 13% are mine mill. A wide variety of chrome ore sudan options are available to you, Good Feedback Alluvial Tin Jig Plant in .

what does a gold mill plant consist of . Teranga Gold Reports Positive Feasibility Initial gold reserves of million ounces update expected in H1 2018 Major construction expected to commence in Q2 2018.

Feb 12, 2018· SAG Mill. Semi autogenous grinding (SAG)technology, as an effective measure to reduce the capital investment and production cost, has been widely recognized. It has been widely applied in nonmetal mineral processing, ferrous metal mineral processing and nonferrous metal mineral processing, and is being popularized gradually in gold processing ...

small gold crushing and milling plant . Mill (grinding) Wikipedia. A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them.

what does a gold mill plant consist of . Teranga Gold Reports Positive Feasibility Initial gold reserves of million ounces update expected in H1 2018 Major construction expected to commence in Q2 2018.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Gold Milling Plant Newest crusher, grinding mill, mobile crusher plant crushing plant and grinding mill are widely used in the industry of mining, metallurgy, building materials, traffic, water conservancy and so on. chat online. Click Me ^_^

At the processing plant, gold and silver are extracted from the ore. The processing plant alternates between treating ore from the Martha Mine open pit and from the Favona underground mine. ... Ore processing consists of the following stages: crushing and grinding of the ore; ... the ore is fed into the semi autogenous grinding (SAG) mill (4 ...

Sep 23, 2017· The 10 tons per hour rock gold ore process plant in Zimbabwe Africa, the plant adopted machines such as jaw cruher, hammer crusher, ball mill, spiral classifier, jig machine, centrifugal gold ...

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

The gold cyanide complex is then extracted from the pulp or slurry by adsorption onto activated carbon. CIL stands for carboninleach. This is a gold extraction process called cyanidation where carbon is added to the leach tanks (or reaction vessel) so that leaching and adsorption take place in .

gold ore milling plant. Gold Ore Processing Plant . The ore is milled in a 6 MW, gold milling plant in open circuit. Gold ore is transported directly inside the open pit in 90 tonne material is either stockpiled about the pad or straight tipped into the principal gold crushing and mill plant reduces the ore down to a great deal less than about 300 mill metres in a single

This plant processes 4 million tons of ore per year with an average gold content of ounces of gold per ton of ore. Approximately 85% of the gold is recovered in the plant. From the ball and/or autogenous mill, slurry is pumped to the CIL leach tanks where lime adjusts the pH, if necessary, and it is agitated for the desired period of time.

offers 3,229 ball mill gold plant products. About 6% of these are mineral separator, 1% are other mining machines, and 1% are other machinery industry equipment. A wide variety of ball mill gold plant options are available to you, such as gravity .

Aug 11, 2015· Gold plant at my mine. Ancient gold smelting rare today. extract recovery process of refining gold to remove any impurities Duration: 10:32. Archimedes Channel 1,353,874 views

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore ...

WhatsApp)

WhatsApp)