Coal Mines YouTube

Jun 17, 2016· The goal of coal mining is to obtain coal from the ground. Coal is valued for its energy content, and, since the 1880s, has been widely used to generate electricity. Steel and cement industries ...

WhatsApp)

WhatsApp)

Jun 17, 2016· The goal of coal mining is to obtain coal from the ground. Coal is valued for its energy content, and, since the 1880s, has been widely used to generate electricity. Steel and cement industries ...

Earth movers are used regularly with above ground mining and transport waste material out of the mining area. They can also be used for digging as well to clear materials. Feeding and conveying equipment works within the processing system and feeds the crushing equipment raw materials, and moves it along to other machinery.

As of 2017 Turkey was 11th in the list of countries by coal production, and mined % of the world''s coal, with lignite and subbituminous deposits widespread throughout the country. Due to the country''s geology, there is no hard coal, which has a higher energy density (over 7,250 kcal/kg), within 1000 m of the surface. All coal deposits are owned by the state but over half of mining is ...

PGNAA or PFTNA analyser and blending software that measure sulfur, ash, moisture, calorific value, and other to control coal quality and blend consistency in coal mining and production. Contact a coal analysis sales representative to discuss your coal analyzer today or call TollFREE .

Dec 21, 2015· Underground specialized mining equipment such as trucks, loaders, diggers etc. are used to excavate the material and are normally hauled to the surface with skips or lifts for further processing. Drilling is normally required to place explosive charges to liberate the minerals from the overburden material.

Rock dusters are pressurized pieces of equipment that coal miners use to spray inert mineral dust over highly flammable coal dust. The inert dust helps prevent accidental fires and explosions. Shuttle Cars and Scoops Coalminers use electricpowered shuttle cars to transport coal from the coal bed to .

The form of Anemometer generally used in coal mining consists of a metal ring within which is set a rotating propeller of blade. The air current striking the inclined blades rotates the bane, the number of revolutions being recorded on the face of the dial by means of a series of gears.

Underground mining operations around the world pose similar risks to worker safety and health. Though different techniques are used to extract base metals, precious metals, nonmetallic minerals, diamonds and coal, the hazards do not differ that much. The deeper the mine, however, the greater the risk. Safety Challenges in Underground Mines

Coal miners leaving an American mine at the end of a shift (April 1974) Surface coal mining in Wyoming in the United States. A coal mine in Bihar, India. A coal mine in Frameries, Belgium.. Coal mining is the process of extracting coal from the ground. Coal is valued for its energy content and since the 1880s, has been widely used to generate electricity. ...

Scrapers are used in coal mines for cutting and transporting weathered sandstone as well as coal. The coal excavated by it is however smaller in size. A Scraper may take 5 to 6 minutes for a complete cycle of loading and unloading if the total upanddown distance of a trip is nearly 300 m.

Anemometers, as used in mines, were produced in two styles, the Biram style which have the the dials and vanes on the same plane and the offset style which has the dials perpendicular to the vanes. Anemometers are generally collected by mining collectors and scientific instrument collectors.

When the coal is dumped the miner gets credit for the weight of coal. The photo above shows a wooden tamping tool and a metal needle with a two instruments were used when a miner had to blast a coal vein to break the coal from the vein. A hole is drilled into the vein of coal.

usually found near faces of entries where coal is being mined. To maintain methane concentration below 1 pct ... The instrument used for this research had a sampling rate of 40 Hz, and sample data was reported at 1 Hz. ... simulate a mining entry with a m (7ft) high roof and ribs 5 m (16½ ft) apart. For half of the tests the entry

Coal mining is the process of extracting coal from the ground. Coal is valued for its energy content and since the 1880s, has been widely used to generate electricity. Steel and cement industries use coal as a fuel for extraction of iron from iron ore and for cement production. In the United Kingdom and South Africa, a coal mine and its structures are a colliery, a coal mine is a ''pit'', and ...

The first use of trucks for largescale openpit haulage in metal mines in the United States was, so far as the authors are aware, at the United Verde mine. According to Alenius, the original plan was to mine the material below the 160foot level by gloryholing, and in 1924 several glory holes were started.

Collecting coal scrip. Coal scrip was given to workers instead of United States money. Collectible coal scrip usually was made by the Childs Company, the Ingle Company, or Osborne Register Company. While copper and nickel are the most common, you can find coal scrip made of brass, aluminum, fiber, Bakelite, rubber, zinc, and steel.

Changes evolved through a need to make a safer underground environment for the thousands of miners employed in Cape Breton''s coal industry. It has been said that perhaps the most beneficial development in mining equipment was the methanometre, an instrument used to measure the percentage of methane in the air.

One of the instruments used back then was the dial: a compass made especially for underground purposes. This method was often inaccurate; iron tools or iron ore deposits in the mine tended to interfere with the needle of the compass. ... a form of underground coal mining whereby a long wall of coal is mined in a single ''slice''.

Aug 4, 2016 Explore China Coal China''s board "Safeprotection Instrument" on Pinterest. See more ideas about Fire extinguishers, Coal mining, Fire extinguisher.

May 22, 2020· Coal mining is the process of extracting coal from the ground. Coal is valued for its energy content, and, since the 1880s, has been widely used to generate electricity. Steel and cement industries use coal as a fuel for extraction of iron from iron ore and for cement production.

The United Kingdom Mining Research Establishment instrument, used as the basis for coal mine respirable dust standards, had been designed specifically to match the United Kingdom British Medical Research Council (BMRC) criterion. The personal sampler is used with a multiplier to convert readings to the BMRC criterion.

Geophysical Intrument For Coal Mine. geophysical intrument for coal mine Overview of coal mining problems safe and efficient coal extraction is often compromised by a variety of geological and mininginduced problems in this paper we will focus on the five most commonly occurring problems and explain how the application of selected geophysical methods can play a key role in addressing these ...

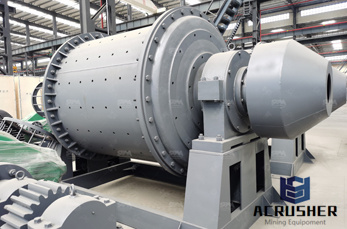

instrument used in coal mining crusher Lizenithne Mining RitchieWiki It goes through crushing, grinding process, then make into powder.... ore crusher, coal crusher, cement mill, concrete crusher, and gold... Under this, hammer crusher or impact crusher .

Instrument Used In Coal Mining Crusher. Instrument used in coper 20 2014nbsp018332according to the epa there are 112 sites like treece in the united states including jefferson is home to an eroding dam holding back mining waste from abandoned copper mines spokane indian reservation in washington state where piles of toxic rock remain from uranium mining .

WhatsApp)

WhatsApp)