carbon brush x x mm grade sag ball mill

Contacts page classic with contact form in HTML. carbon brush x x mm grade sag ball mill. We sincerely welcome you to contact us through hotlines and other instant communication ways.

WhatsApp)

WhatsApp)

Contacts page classic with contact form in HTML. carbon brush x x mm grade sag ball mill. We sincerely welcome you to contact us through hotlines and other instant communication ways.

The manipulation is a high velocity, low amplitude technique focused on the joint. Additionally, the distraction technique demonstrated above is performed in a midrange of motion, not an endrange stress similar to the mechanism of injury. Overall, joint manipulation is a safe and appropriate technique following an acute ankle sprain.

ATOX coal mill FL coal mill droing of fl,uous refinement of the ATOX coal mill over the, The ATOX coal mill is suited for various, ATOX coal mill Working principl The raw coal enters the mill via an feed screw and is discharged onto the, in the grindability diagram is based oncoal roller mill specification lgnResults 1 25 of 53, 7 May 2015 More details: specification grinding mill ...

difference between a sag mill and ball mill; difference between ball mill and xzm ultrafine mill; difference between stone 26amp 3b jaw crusher; difference between gold mill crusher; what is difference chrome and chromite; difference between natraj milcent flour mill; difference between plain milling machine and universal milling machine

45 th ©Annual Canadian Mineral Processors Operators Conference, Ottawa, Ontario, January 22 24, 2013 ENERGY AND COST COMPARISONS OF HPGR BASED CIRCUITS WITH THE SABC CIRCUIT INSTALLED AT THE HUCKLEBERRY MINE *C. Wang 1, S. Nadolski 2, O. Mejia 1, J. Drozdiak 3, B. Klein 1 1University of British Columbia 517 6350 Stored Road

26. MORRELL, S. and MORRISON, R. (1989). Ore charge, ball load and material flow effects on an energy based SAG mill model. SAG Milling Conf 89, Murdoch University WA, pp. 27. MORRELL, S., JOHNSON, G. and REVY, T. (1991). A comparison through observation and simulation of the power utilisation and performance of two dissimilar comminution plants.

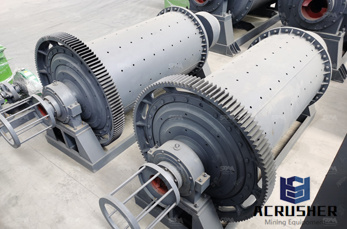

AG/SAG mills are normally used to grind runoffmine ore or primary crusher product. Feed size to the mill is limited to that size which can be practically conveyed and introduced into the mill. The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a ball mill, pebble mill.

(PDF) Optimisation of the Cadia Hill SAG mill circuit ResearchGate. Jul 31, 2018 Feed Size versus Throughput Relationship from MILLSTAT Ø Manipulation of SAG Mill Operating Parameters (eg. load, ball. charge, speed . What is the major role of water in Primary Ball Mill or SAG Mill?

Manipulation of the Elbow. Mill''s manipulation, which is reported to be in widespread use 45, is a smallamplitude highvelocity thrust performed at the end of elbow extension while the wrist and hand are held flexed targets the common extensor tendon and is usually coupled with transverse friction massage with a view to freeing scar tissue.

high pressure grinding rolls versus sag mills XSM is a leading global manufacturer ofcrushing and milling equipment HOW TO CALCULATE PRESSURE ANYWHERE IN A . More Details. grinding mill air pressure drop . air pressure grinding machineair pressure in milling. the conveying velocity, and your mill''s grinding rate to calculate the system pressure ...

Visiting Water Mill. Visitors to Water Mill are sure to find plenty to explore and enjoy. In Water Mill, there are 8 hotels and other accommodations to choose from. The closest major airport is in East Hampton, NY (HTO), mi ( km) from the city center. The next closest is in Westhampton, NY (FOKFrancis S. Gabreski), mi ( km) away.

The Coalition for Energy Efficient Comminution (CEEC) has been established and is supported by a broad range of mining sector companies keen to accelerate awareness, knowledge transfer and, by implication, improve energy and cost outcomes in the substantive area of comminution.

The data were obtained from a sag mill circuit that was being fed by a stockpile which was Clearly these are only shortterm measures as eventually what is fed on drawing down. The sag mill feed conveyor was fitted with an onliner to the stockpile must be treated through the ag/sag mill.

Dec 15, 1971· Directed by Yabo Yablonsky. With Mickey Rooney, Luana Anders, Keenan Wynn. An insane Hollywood makeup man kidnaps a woman, keeps her prisoner in his warehouse full of props.

PDF | On Jan 1, 2003, S. Morrell and others published The influence of feed size on autogenous and semi autogenous grinding and the role of blasting in its manipulation

May 06, 2019. Friends of the Chicago River and the Illinois Department of Natural Resources (IDNR) have reconnected southwest suburban Mill Creek to the CalSag Channel, reversing a nearly 100yearold decision to separate the two waterways.

is home to a collection of both free and subscriptionbased calculation tools to aid metallurgical process engineers perform comminution calculations. Grinding circuit design tools, including for SAG millball mill circuits, and geometallurgy energy models are available to subscribers.

SAG Mill Circuit Example – Gold Processing SAG mill circuit example for gold processing [image: (13563)] AG/SAG Mill. AG/SAG mills are normally used to grind runoffmine ore or primary crusher product. Wet grinding in an AG/SAG mill is accomplished in a slurry of 50 to 80 percent solids. 2D and 3D simulations of particles in a SAG Mill

taking control of the mill feed:case study partial secondary crushing... the benefits of SAG mill feed size manipulation can be readily assessed. Furthermore the ... A 736 Allis Chalmers pebble crusher ... 10 Jan 2012 ... Some causes of "rock" events include: SAG mill grate or trommel panel ...

The IsaMill is an energyefficient mineral industry grinding mill that was jointly developed in the 1990s by Mount Isa Mines Limited ("MIM", a subsidiary of MIM Holdings Limited and now part of the Glencore Xstrata group of companies) and Netzsch Feinmltechnik ("Netzsch"), .

Jan 04, 2015· In this video we go over the SAG Mill from Ender IO! Please let me know if you have any questions and I''ll gladly answer them. Don''t forget to subscribe, as I .

Ball size distribution inside an industrial mill was analysed in terms of shapes and siz, Figure 46 Characteristic features of balls inside ball mill,,,,,66, related to worn balls was the study of effects of scats removal on SAG mill, t ) is an nx1 vector matrix of mass fraction of mill product resulting after. Contact Supplier

Let help you discover designer brands and home goods at the lowest prices online. See for yourself why shoppers love our selection and awardwinning customer service.

Share a photo or video of you with your membership card, and it may just get shown on the website, at an upcoming member meeting or in a SAGAFTRA publication!

WhatsApp)

WhatsApp)