Jaw Crusher for Mining, Construction and Aggregate Industries.

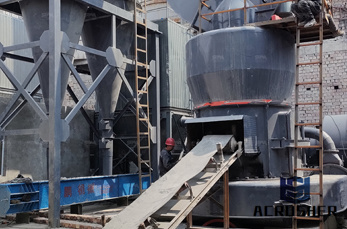

DOVE provides Jaw Crusher for downsizing of materials in mining, constructions and aggregate industries. Required in a HardRock Deposit mining project.

WhatsApp)

WhatsApp)

DOVE provides Jaw Crusher for downsizing of materials in mining, constructions and aggregate industries. Required in a HardRock Deposit mining project.

Comminution is the reduction of solid materials from one average particle size to a smaller average particle size, by crushing, grinding, cutting, vibrating, or other processes. In geology, it occurs naturally during faulting in the upper part of the Earth''s crust. In industry, it is an important unit operation in mineral processing, ceramics, electronics, and other fields, accomplished with ...

First class toll milling to the local gold mining industry FMR Investments was formed in 2007 when specialist hard rock underground mining services provider Barminco – founded in 1987, divested ...

The i350 is a family member of the Falcon Gravity Concentrators Gold Mining Equipment which has revolutionizing the world of alluvial gold mining and dredging the same way its little brother, the i150, has impacted the world of hard rock mining. This is a gravimetric mineral concentrator that uses enhanced gravity (G''s) to concentrate the ''free'' heavy minerals.

The GRG (Gravity Recovery Gold) testing is available at MetSolve Labs. The number 1 application for iCON Mining Equipment worldwide is Hard Rock Mining. The 2tph capacity and the ability to recover fine, flat milled gold are ideal for iCON. The major mines of the world use gravity concentration in their grinding circuits.

Underground hard rock mining refers to various underground mining techniques used to excavate hard minerals, usually those containing metals such as ore containing gold, silver, iron, copper, zinc, nickel, tin and lead, but also involves using the same techniques for .

Jan 15, 2013· ***Posted a second video of the impact mill finished and being tested see it here: Like us on Facebook to stay current with ...

Mar 02, 2018· Colossal Alaska gold project quietly winning approval ... But the first substantial hard rock gold mining didn''t occur until the 1980s. ... The sheer size.

Gold Mining Equipment List. Making a complete list of gold mining equipment starts with defining the type of gold mining you are doing and the budget you have at your disposal. The type of mining relates to hard rock, eluvial, or placer; alluvial deposits. The capital budget you have to invest in buying your equipment with dictate the scale at ...

Medium scale mining equipment is available in a variety of sizes for a variety of recoveries from tin, chrome and tantalite right through to gold. Appropriate Process Technologies (APT) employees have decades worth of experience in the mining industry; we know what you need and we can provide mining

Mining Is Facing a Critical Skills Shortage. Face the Challenge Head On with Our Enterprise Solutions for Mining Companies. Tailor the ideal solution to help you onboard new hires faster, cross train high potential employees better, and develop your specialists'' knowledge earlier in their career

Mar 30, 2017· This is our fourth video in our five part series of our trip to Kenya to install a shaker table to help eliminate the use of mercury by the smalls scale gold miners. We met with Julius who is the ...

BRAND NEW HARD ROCK MINING equipment available for immediate sale, from Mt. Baker Mining and Metals. We are a USA manufacturer located in Bellingham, WA. Call us today at (360) for more information. 3''x6'' Ball Mill (1TPH), complete with drive, 20hp motor, balls, frame 31,100

Hard Rock UniversityHard Rock Gold Mining Resources. HRU Mission Statement. Lesson 1 Where Does Gold Come From. ... Lesson 21 Size Matters: California Prospect 1. ... Lesson 24 Improved Method to Pan Micro Fine Gold. Lesson 25 Is Your Grinding Circuit a Gold Trap? Lesson 26 The Mining Project Economics Estimator. Lesson 27 The Gold ...

Very economical for high volumes of typical alluvial or milled hardrock ores Adaptable to any existing classifying circuit Multiple units can be connected in simultaneous feed for higher volume throughput Performs well with turbid water, great for recycle loop applications (ponds). ... GOLD CONCENTRATOR, gold concentrators, GOLD ...

The slurry that remains after this process has a very fine particle size. Typically, 80% of the ore particles are less than 70 microns in size (about the same consistency as fine beach sand). Such a fine particle size is required for gold liberation – the size required for the cyanide to be able to ''see'' the gold in the leaching process.

• Investigates the feasibility of a novel AGCrusherHPGR circuit using rock samples from a large coppergold mining project. The approach was to develop and evaluate the circuit design for hightonnage operations with mixed hardness

The Cyanidation Process or CYANIDE LEACHING is ''most notably used in the recovery of gold. Safety and environmental concerns are of prime importance in the operation of a cyanidation plant. As we get farther into this type of recovery you will see why. The preparation of the ore for processing is similar to flotation. The ore must be ground to a specific size before it can be treated.

Oct 01, 2018· asked three experts at to discuss ways for mining companies to improve energy efficiency in comminution. ... is key in determining the right comminution circuit design. In hard ...

The JCRD, APT''s large scale hard rock crusher plant. This plant is manufactured inhouse, meaning that it is engineered, designed and built under one roof. APT mining equipment is compact yet efficient, affordable yet not compromising on quality. Contact us for your large scale hard rock crusher pla

Scrap metal recycling uses screen openings up to 3″ x 3″ in the larger primary hammer mills, and punch plate holes as small as 1/4″ in our printed circuit board (PCB) recycling hammer mills. Mt. Baker Mining and Metals'' hammer mills are industrial grade, continuous duty machines.

Sep 07, 2019· 03 August 2019 02:21 am. thinking of making a 3 head stamp battery ( rock crusher ) just getting steel together at the moment and maybe a reinforced old trailer as i want it to be portable with a water feed for the dust it will be only a primary crusher to get big stones like a foot size chunks of quartz down to say finger nail size then thinking of 2 roller mills to crush it even finer to ...

Aug 25, 2016· Vat leaching is a highproduction rate metal extraction process, solutions are used to extract gold from ores industrial washing of quartz sand industrial process quartz mining.

There are also some smallscale hard rock goldmining operations. Alaska currently produces more gold (in 2015: 873,984 troy oz from hard rock mines, and 74,360 troy oz (fiveyear average) from placer deposits) than any state except Nevada. In 2015, gold worth billion accounted for 37% of the mining wealth produced in Alaska.

WhatsApp)

WhatsApp)