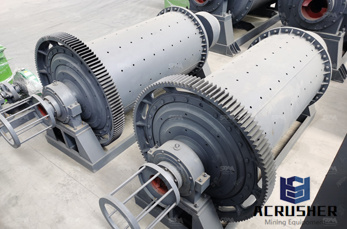

Cement Ball Mill,Mini Cement Plant India

Mini Cement Plant. We are offering mini cement plant machinery like ball mills, kiln, cooler, conveyors, bucket elevators on turn key basis up to 600 tons per day capacity. View Details » Send Enquiry »

WhatsApp)

WhatsApp)

Mini Cement Plant. We are offering mini cement plant machinery like ball mills, kiln, cooler, conveyors, bucket elevators on turn key basis up to 600 tons per day capacity. View Details » Send Enquiry »

A wide variety of cost of cement plant options are available to you, such as free samples, paid samples. There are 7,420 cost of cement plant suppliers, mainly located in Asia. The top supplying countries or regions are China, Vietnam, and India, which supply 99%, 1%, and 1% of cost of cement plant .

Feb 10, 2016· VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300350 – TPH) and before implementing the project, we would like to

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry. We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

cost to set up mini cement plant in india Global Cement Market Report, Size, Share, Trends, Outlook According to latest research report, the global cement market share and size reached a volume of more than 5 Billion Tons in Market is further projected to reach around Billion Tons by 2024, exhibiting a CAGR of around % during ...

Apr 21, 2018· Y_326 How to Start a Mini Cement Plant. Cement Manufacturing Industry. Cement Business. India is the second largest producer of cement in the world. No wonder, India''s cement industry is a vital ...

Aug 26, 2016· Also concrete plants and more for mini cement plant for sale in ap india mini cement plant for sale in ap india. mini stone crushing equipment uk; mobile concrete mini mixer for sale; complete ...

Since the Mini Cement Plants with production capacity of 50 and 100 Tons per day, can be installed at smaller deposits of limestone areas and can encourage small entrepreneurs to establish small cement plant in rural area to develop local employment.

I am assuming you intend to establish a cement manufacturing mill/plant, and be a part of the larger industry. You don''t set up a Industry. On that note, starting a cement manufacturing business requires serious time, energy, and capital investmen...

CEMENT PLANT / CEMENT GRINDING UNIT . We are manufacturers and exporters of cement plants like mini cement plant, clinker grinding unit, cement bagging plant and many others. We take in charge the execution of complete Minicement plants and their units. Our Minicement plant machine design made by our experienced team.

Oct 24, 2016· We are the supplier of rice milling machine, rice milling plant, rice dryer machine and related machine. Our rice milling equipment provides higher yields, less brokens, better taste and ...

Need a batch plant to load your MiniMax Concrete Mixer? Or if you have your own small concrete Mixer Truck or Trailer we will build you a batch plant so you can make your own concrete. Use these batching plants on your jobs, for your small concrete delivery business or take it .

How Much Cost Is Required For Small Cement Plant Setup In India Business Nairaland ... for cement product begins with 200,000 tonnes for the year 2004, and will reach to 1,300,000 tonnes by the year 2010. MiniCement Plants (MCPs) can be established with varying production capacities. ... such as cement crusher, cement mill, conveyor belt ...

Cement production line: cement making plant is used in cement raw material crushing plant. Limestone crushing: limestone is the main raw material for cement making, but since natural limestone is usually big, we use limestone crusher to crush.

I am located at medabad, Gujarat, India. I want to start a steel mini mill. I want to have rough cost estimates of the whole process. I also want to have the financial information about starting a mini mill. And how much space is required for a steel mini plant.

Dec 16, 2017· Mini steel mills are normally secondary steel producers located near consumer markets based mainly on steel/iron scrap of different grades. The mini steel plant comprises of steel melting using induction furnace or electric furnace to melt scrap...

Specializing in the sale of second hand cement plant equipment, and complete used cement plants. In addition to used and new surplus Cement Plant Equipment (rotary kilns, ball mills, vertical roller mills), NMI deals in many other types of machinery, including used equipment for Bulk Material Handling, Crushing, Grinding, Industrial Mineral Processing, and Power Plants

Flour Mill Business Plant Setup Machinery. First of all, you have to secure a location for the manufaacturing operation. Check the available transportation facility, electricity, water, semiskilled manpower and drainage facility. For setting up a small scale unit with the entire product range, you will need to have 3000 Sq Ft built up area ...

If you are planning to set up a mini plant for making your own animal feed pellets on farm or start a small feed pellets manufacturing business, this small plant should be your best choice! Equipment Details of the Small Poultry Feed Pellet Plant. The followings are brief introduction of each equipment included in this small feed mill plant.

If you are a beginner and need any help on starting your poultry feed processing business, here are some tips to help you make the best customized feed mill business plan and set up your own poultry feed plant step by step. small to medium scale animal poultry feed plant layout design See more

This newly developed mini soybean oil processing unit is designed for those who want to start a small scale soy bean oil pressing plant with limited cost budget. It is a great choice for mini vegetable oil mill or as initial investment of o

A VSK Mini Cement Plant is smaller in size as compare to a normal Rotary Kiln Cement Plant. VSK Cement Plant is known for occupying less space, high production capacity and feasibility. We are counted among the distinguished VSK Cement Plants manufacturers and exporters based in India. Our high efficiency, cost effective,

We, Technomart Engineers Private Limited from 2015 are manufacturing a highquality range of Cement and Fertilizer products range consists of Cement Plant, Ball Mill, and Fertilizer Plant. All offered products are designed using quality tested material under the direction of our domain experts at wellequipped infrastructure unit.

Aug 25, 2013· Cost To Setup Mini Cement Plant In India ... The second phase is handled in a cement grinding mill, which may be located in a different place to the clinker plant. Gypsum and possibly additional cementitious or inert materials are added to the clinker. All constituents are ground leading to a fine and homogenous powder.

WhatsApp)

WhatsApp)