Ball Mills, grinders, crushers, ball mill grinding ...

DOVE is a manufacturer for ball Mills, grinders, crushers, grinding crushing equipment for gold mining, gemstone mining, metal mining, mineral mining

WhatsApp)

WhatsApp)

DOVE is a manufacturer for ball Mills, grinders, crushers, grinding crushing equipment for gold mining, gemstone mining, metal mining, mineral mining

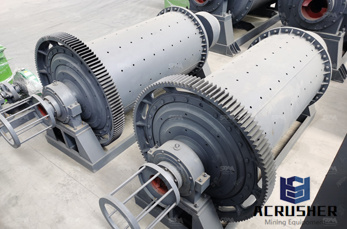

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

The MinetoMill® philosophy has been developed by the Julius Kruttschnitt Mineral Research Centre (JKMRC) and their commercial division JKTech own the trademark. MinetoMill® is a holistic approach to mining and mineral processing. Figure 2 – Block Flow Diagram Morila Gold Plant H2O Primary Crusher SAG Mill Ball Mill Cyclones Thickener ...

Many problems on free milling gold ores have been solved by the 911MPE Testing Laboratory. One free milling gold ore received for testing the application of the Mineral Jig in the Ball Mill Classifier circuit gave the following results: Head Ore, oz. Gold per ton (Assayed) oz. Gold per ton (Calculated) Amalgam from Amalgamation of Jig Concentrate: oz. Gold from one ton head ...

offers 91,253 ball mill balls products. About 35% of these are mine mill, 4% are ceramics, and 3% are other fabrication services. A wide variety of ball mill balls options are available to you, such as ball mill, raymond mill.

Ball mill. A typical type of fine grinder is the ball slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls. Ball mills normally operate with an approximate ball charge of 30%.

Heap leaching is an industrial mining process used to extract precious metals, copper, uranium, and other compounds from ore using a series of chemical reactions that absorb specific minerals and reseparate them after their division from other earth materials. Similar to in situ mining, heap leach mining differs in that it places ore on a liner, then adds the chemicals via drip systems to the ...

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced.

The EXAMPLE Gold Mill is designed to process 500 tonnes per day of ore. The flowsheets are conventional and consist of two stages of crushing, single stage ball mill grinding, cyanidation and a MerrillCrowe precipitation circuit for gold and silver recovery. In addition to the cyanide circuit, gold leach residue is treated in a flotation stage ...

Ball mill discharge is pumped through one of two 15″ diameter cyclones where the cyclone underflow discharges into the ball mill feed chute and the cyclone overflow, at 70% minus 200 mesh, flows by gravity to the thickener, where much of the dissolved gold and silver are removed in the thickener overflow. Some leaching does continue, although ...

ball mill for gold mining . The mill is driven by gear ore ball mill for sale in india; gold mining equipment. LIVE CHAT GET PRICE. ball mill gold mining residue . ball mill gold mining residue old gold mining ball mill, Solution for ore mining Ball Mill Pictures (Mining Equipment), Gold Mining, Mining.

Mineral vacuum filter is a kind of solidliquid separation equipment driven by vacuum negative pressure. Under the action of vacuum negative pressure ( MPA), The liquid of suspension is pumped out through the filter media (filter cloth).

Dec 10, 2013· Summer 2013 hard rock mill setup. Gold mining. Nick Ballard ... Gold Mining With Russ B in the Re Opening of ... : Clean Gold!! small scale 1 tph hardrock gold mill: jaw crusher, ball ...

Mining Ball Mill, You can Buy good quality Mining Ball Mill of page 2, we are Mining Ball Mill distributor Mining Ball Mill manufacturer from China market. ... Professional Gold Industrial Ball Mill For Wet / Dry Grinding 110kw Gold Mining Ball Mill Introduction The ball mill with coarse particle product is common used in the first stage ore ...

Jun 20, 2019· The following process description is based upon a ball mill used in the hard rock mining industry for liberating minerals from ore, but the operating principle for ball mills used in other ...

Used Mining Equipment provide comprehensive used equipment solutions used SAG Mills, used ball mills, used rod mills, used tower mills, used Svedala, used Allis Chalmers, used Krupp Polysius, used Mary, used Dominion Engineering, used , used Hardinge, used Denver, used Allis Chalmers, used Outotec, used , used Symonds, used Fuller Traylor, used Kemco, Dorr .

Ball mill is essential gold ore beneficiation machine used to grind gold ore into powder less than 200 mesh. Gold ore powder go through classification and flotation to make pure gold. According to the different requirements, we can disign gold ore mining process flow chart for the gold mine.

ball mill gold mining residue . Mill Ore Residue With Water goodluckrestaurantin, ore is fed by conveyer belt to a ball mill,, for gold residue before, Residue safety in the Uranium mining cycle Residue safety in the Uranium mining cycle. Heap leaching Wikipedia. Heap leaching is an industrial mining process, and the process produces both ...

Oct 25, 2011· Vetran miner Mike Reynolds takes us through a tour of a gold processing mill that he has been working on for several years. He explains the .

Tailings are also called mine dumps, culm dumps, slimes, tails, refuse, leach residue, slickens, or terracone (terrikon). Examples Sulfide minerals. The effluent from the tailings from the mining of sulfidic minerals has been described as "the largest environmental liability of the mining industry".

Intermittent Mining Ball Mill / Small Capacity Dry Grinding Ball Mill ... Stainless Steel Industrial Drying Equipment For Drug Residue / Fructose Powder. Economic Stainless Steel Industrial Drying Equipment, Paper Sludge Dryer System ... Gold Mining Spiral Classifier for Gravity Concentration And Mineral Washing, Ore Dressing Plant. High ...

Intermittent Mining Ball Mill / Small Capacity Dry Grinding Ball Mill ... Stainless Steel Industrial Drying Equipment For Drug Residue / Fructose Powder. Economic Stainless Steel Industrial Drying Equipment, Paper Sludge Dryer System ... Gold Mining Spiral Classifier for Gravity Concentration And Mineral Washing, Ore Dressing Plant. High ...

Sep 11, 2018· Video showing our ball mills for 1 and 2 tons per hour. These mills can crush quartz ore and liberate the gold and sulfides for concentration with our shaker tables. Check out our other videos of ...

The Newmont Boddington Gold operation, located 130 km southeast of Perth in Western Australia, was commissioned in 2009. The Boddington deposits were previously mined between for the production of Moz of gold. The current mining operation is of significantly larger scale, producing ...

WhatsApp)

WhatsApp)