RoM BALL MILLS A COMPARISON WITH AG/SAG MILLING

II314 RoM Ball mills – a comparison with AG/SAG Milling Aubrey N. Mainza1 and Malcolm S. Powell 1 1Mineral Processing Research Unit, University of Cape Town, Rondebosch, 7700, South Africa ...

WhatsApp)

WhatsApp)

II314 RoM Ball mills – a comparison with AG/SAG Milling Aubrey N. Mainza1 and Malcolm S. Powell 1 1Mineral Processing Research Unit, University of Cape Town, Rondebosch, 7700, South Africa ...

Oct 12, 2017· The ball charge of a SAG mill is about 29% to 30%. By friction and influence of tumbling balls inside rotating cylinder grinds the raw material to the required fineness. The internal machinery of ball mill grinds the raw material into the powderlike material, And if extreme fineness and refinery are required then rotation go on continue.

offers flexible autogenous (AG) mills, semiautogenous (SAG) mills, ball and pebble mills, as well as stirred mills to fit your needs. Wide offering. Grinding mills, spare and wear parts as well as maintenance and optimization services. Efficiency through automatized operation.

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula The mill speed is typically defined as the percent of the Theoretical ...

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ROOLVLRQ 5ROOLQJ ZLWK QLSSLQJ ... Figure Effect of mill filling on power draft for ball mills. The data is taken from Rexnord Process Machinery ... LG A mill power equation for SAG mills. Minerals and Metallurgical Processing. Feb 1990 pp5762.

Even though production was dramatically improved, the product size of the secondary ball milling was reduced and recovery increased. The results in SAGMill line 2 are even more dramatic. Because of segregation on the coarse feed stockpile, SAGmill 2 receives a higher percentage of coarse material.

Grinding Circuit Modelling Documentation. This documentation describes the operating and underlying mathematics of the grinding circuit modelling program. It is intended to be used by the model users who want to operate and understand the functioning of grinding models.

semiautogenous (SAG) mill and two ball mills, each with 13 megawatts (MW) of installed power, was expected to be SAG mill limited when treating competent basement rock. Ausenco Services Pty Ltd (Ausenco), was engaged to help optimise and enhance the productivity of the Phu Kham comminution circuit over an eightmonth period.

afo operate a SAG mill, ball mill and pebble crusher (SABC) circuit that processes a range of primary ore of varying hardness from different pits which is blended with soft oxide material. The PTI study focussed on ball mill limited material from the Apensu open pit.

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell''s inside surface. This is the rotational speed where balls will not fall away from the mill''s shell.

Buy used Sagmills from King Industries. We can help guide you to the best solution for your equipment needs.

supported grinding mills up to the largest sizes. SAG/ball mill circuit incorporating pebble crushers and a POLYCOM® highpressure grinding roll. SAG and ball mill for gold ore grinding. One of three SAG mills with m diameter and 2 x 4000 kW drive power. These mills operate in conjunction with ball mills for iron ore grinding in Iran.

offers 1,291 sag mill products. About 12% of these are mine mill, 10% are casting, and 1% are grinding equipment. A wide variety of sag mill options are available to you, such as ball mill, raymond mill.

DEM SIMULATION OF MILL CHARGE IN 3D VIA GPU COMPUTING * and, 3,, 3 ... SAG and ball mills are reported. The simulation of AG and SAG mills are completed in less than 8 hours. The ball mill simulation with million spheres is completed in 27 hours. In the near future, these compute times can be halved ...

The Selection and Design of Mill Liners . ... Was generally used for mill liners (AG, SAG and Ball) prior to the movement to higher carbon content steels. It has excellent wear characteristics with some impact resistance, generally now used for discharge grates where

intermediate size ready for final grinding in a ball mill, pebble mill, or VERTIMILLTM. Wet grinding is accomplished in a slurry of 50 to 80 percent solids. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

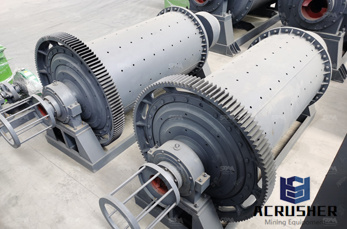

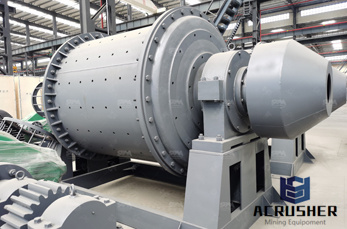

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

The world''s most widelyused rubber mill liners. Kosga has been providing products to the global mining industry for more than 40 the combination of experience and technology, Kosga''s various AG, SAG and ball mill rubber linings are suitable for all existing brands in the market.

Feb 12, 2018· SAG Mill. Semi autogenous grinding (SAG)technology, as an effective measure to reduce the capital investment and production cost, has been widely recognized. It has been widely applied in nonmetal mineral processing, ferrous metal mineral processing and nonferrous metal mineral processing, and is being popularized gradually in gold processing ...

Optimization of mill performance by using online ball and pulp measurements by B. Clermont* and B. de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator. Comminution is responsible for 50% of the total mineral processing cost. In today''s global markets, expanding mining groups are trying

Model Predictive Control for SAG Milling in Minerals Processing | 5 Model Predictive Control on a SAG Mill and Ball Mills The solution for the SAG Mill is an adaptive controller which controls mill load using direct mill weight measurement or indirectly from bearing oil pressure.

Used Mining Equipment provide comprehensive used equipment solutions used SAG Mills, used ball mills, used rod mills, used tower mills, used Svedala, used Allis Chalmers, used Krupp Polysius, used Mary, used Dominion Engineering, used , used Hardinge, used Denver, used Allis Chalmers, used Outotec, used , used Symonds, used Fuller Traylor, used Kemco, Dorr .

AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill. Because of the range of mill sizes available, AG/SAG milling can often be accomplished with fewer lines than in a conventional rod mill/ball mill circuit. A diagram of types of AG/SAG ...

The SAG Mill is a block added by the EnderIO mod. A machine similar to a Pulverizer or a Macerator. It is used to process resources to produce dust. It accepts energy in the form of Redstone Flux or Minecraft Joule, with an internal buffer of 100,000 RF and consumption of 20 RF per tick.

WhatsApp)

WhatsApp)