Improved Elongation cold rolled Ribbed Bar Production Line ...

Realize high ductility cold rolling ribbed rebar coil delivery. Max rolling speed≥ 1000m/minute. Single line production≥ 100,000ton/Year. This technology save .

WhatsApp)

WhatsApp)

Realize high ductility cold rolling ribbed rebar coil delivery. Max rolling speed≥ 1000m/minute. Single line production≥ 100,000ton/Year. This technology save .

Manufacturer and exporter of rolling mill machines, cold rolling mill machinery, steel rolling mill machinery, material handling equipment, shearing machines, large AC induction motors, high voltage 3 phase cage rotor induction motors, flame proof motors, solid yoke, AC wound rotor motors, energy efficient motors, crane duty motors from Aar Kay Associates, Punjab, India

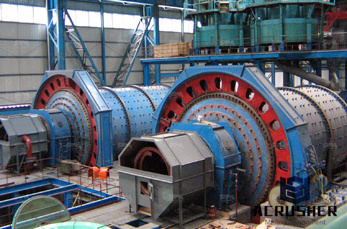

Rolling mill is a equipment used for the the rolling process of the metal and it can complete the entire process of rolling. There''re mainly cold rolling mill, hot rolling mill, continuous casting machine, copper aluminum zinc rolling mill, rolling mill mainly consists of unwinding machine, rolling system, driving system, hydraulic system, control system, roll removal device, etc.

Cold rolling mill is used to roll raw material thickness ≤ 4 mm, width ≤ 800 mm, made of plain carbon steel, low alloy steel, stainless steel and nonferrous metal strip, used for roughing or roughing mill. Equipment composition. This cold rolling mill machine consists of main unit, main motor, reducer, herringbone gear one machine ...

944 cold rolling mill machine products are offered for sale by suppliers on, of which rolling mill accounts for 36%, pipe making machinery accounts for 10%, and tile making machinery accounts for 1%. A wide variety of cold rolling mill machine options are available to you, such as cold rolling mill, hot rolling mill.

Combination: A combination rolling mill is a versatile "twoinone" type of metal rolling mill that permits both 2HI and 4HI rolling operations. Tandem: Tandem rolling mills are used for multiple pass rolling, combining two or more mill stands. Tandem mills are often used with turks heads, edgers, dancers, interstand tensiometers, payoff ...

zmill (20hi cluster type mill) The Waterbury Farrel Sendzimir Rolling Mill is the final answer to the need for highly precise, closetolerance rolled products. Extensive experience in the area has led to the perfecting of these hydraulicallyloaded, gaugecontrolled mills .

Enhancing Technology Co., Ltd. is a leading innovator and supplier for precision cold rolling mill. We continuously create outstanding value for global customers and committed to becoming the preferred supplier of cold rolling .

Our range comprises reduction gear box, cold rolling mill machines, flywheel assembly, roller conveyor, forged rolls, speed increaser and hot saw machine. Designed with the assistance of our engineering excellence, these easy to operate and install machines .

leading in manufacturing, exporting and supplying of Rolling Mills Spares, Coil Packing Machine, Mill And Roll Chocks, Agricultural And Reduction Gearbox, Sugar Mill Machine And Spare Part, etc. The offered products are manufactured using the latest technology and high quality raw material that is procured from trusted vendors of the industry.

bed frame roll forming machine Thickness: Forming stations: 24 Main motor power: *2,220/380V,50/60HZ,3 Phase Drive type: Gear transmission Forming speed: 1215m/min Brief:

Sourcing Guide for Cold Rolling Mill: China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: rolling mill, rolling machine, machinery.

Wuxi Wuye Heavy Industry Machinery Co.,LTD is best Cold Rolling Mill, Rolling Mill Machines and Tandem Rolling Mill supplier, we has good quality products service from China.

Qty. 1 Secondhand cold rolling mill Mfc.: MCC, ABB, IMS Type: 6Hi Cold Rolling Mill Built: 2009 Stopped: 2017 Annual capacity: 220,000 Ton/Year Annual running time (Hour): 6480 Strip Width: 800~1250 mm Thickness Entry: ~ mm Exit: – mm DeCoiler OD: 1000~2000 mm DeCoil ID: 610 mm DeCoil Weight: Max. 25 T Coil OD: 1000~2000 mm Coil ID: 610 mm Coil Weight: Max. 25 T Mill .

After many years'' development on cold roll forming mill, our technology reach first rate in China. Cold rolled steel form machine become our feature products together with other matched equipments such as uncoiler, roll feeder, roll straightener, stacker, conveyor, CNC flame/plasma cutting machine etc.

PREET Machines Limited. We deliver world class quality with latest technology in the most reasonable price.... Preet Machines Limited has successfully designed, built and executed small, medium and mega size Rolling Mills projects like: Hot Strip Rolling Mills, ReBar Rolling Mills, Wire Rod Rolling Mills, Bar Rolling Mills, Light Section Rolling Mills, Medium Section Rolling Mills.

to rolls alone and are also useful for any other component of a machine. The wear parameters in the gap, the contact area of hot rolled material during rolling may be unique but neck loads and contact stress in all other applications (cold rolling.

Our building materials machinery contain roll forming machine, ERW tube mill, slittingcut to length machine and hot dip galvanizing plant. Our machine tools mainly consist of CNC hydraulic press brake, CNC shearing machine,etc.

Baileigh Industrial® Holdings LLC. distributes exclusively manufactured metal and woodworking machinery, trusted by customers ranging from largescale commercial fabrication shops to passionate hobbyists. For 21 years, we''ve created machines .

Dec 30, 2018· Cold rolling is a process by which the sheet metal or strip stock is introduced between rollers and then compressed and squeezed. The amount of strain introduced determines the hardness and other ...

Milling Drilling Reaming Top Turning speeds are adjusted to the feed rate of the mini lathe (/rev.), a depth of cut of, and a tool life of 180 minutes. Material

Rolling mill is a equipment used for the the rolling process of the metal and it can complete the entire process of rolling. There''re mainly cold rolling mill, hot rolling mill, continuous casting machine, copper aluminum zinc rolling mill, rolling mill mainly consists of unwinding machine, rolling system, driving system, hydraulic system, control system, roll .

Cold Rolling Mill Electric Control System:. 1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime. 2. Equipped with movable switch, air break, radiator, transformer electric leakage protector for operation convenience and safety.

In order to sustain various industrial applications, Cold Rolling Mill Machine have been offered to our esteemed clients. These machines are manufactured using qualitative components following stringent working procedures. These working attributes have made our offered range impeccable and also a .

WhatsApp)

WhatsApp)