Gold extraction with BORAX for smallscale miners Rather ...

Oct 17, 2011· Ancient gold smelting rare today. extract recovery process of refining gold to remove any impurities Duration: 10:32. Archimedes Channel 1,454,042 views 10:32

WhatsApp)

WhatsApp)

Oct 17, 2011· Ancient gold smelting rare today. extract recovery process of refining gold to remove any impurities Duration: 10:32. Archimedes Channel 1,454,042 views 10:32

Most of the copper ores mined today are oxide or sulfide ores. Extraction of sulfide ores is covered in more detail in Copper Mining and Extraction: Sulfide Ores (11–14), but is introduced here because an important byproduct of this process is used for the extraction of oxide ores. Pyroprocessing Sulfide Ores Provides Acid for Leaching. Read ...

With ores of higher gold content (, greater than 20 grams of gold per ton of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore and solvent for several hours in large tanks equipped with agitators. For extracting gold from lowgrade ores, heap leaching is practiced.

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page offers a comparative review of gold recovery ...

Gold processing, preparation of the ore for use in various products.. For thousands of years the word gold has connoted something of beauty or value. These images are derived from two properties of gold, its colour and its chemical colour of gold is due to the electronic structure of the gold atom, which absorbs electromagnetic radiation with wavelengths less than 5600 angstroms ...

cyanide process or cyanidation, method for extracting gold from its ore. The ore is first finely ground and may be concentrated by flotation; if it contains certain impurities, it may be roasted. It is then mixed with a dilute solution of sodium cyanide (or potassium or calcium cyanide) while air is bubbled through it.

Dec 20, 2019· Silver and gold are extracted by the cyanide process (Mac Arthur Forrest process). After the preliminary crushing and concentration by froth floatation process, the ore (crushed auriferous rocks in the case of gold) is leached with dilute ( 7%) solution of sodium cyanide made alkaline by adding lime kept agitated by a current of air.

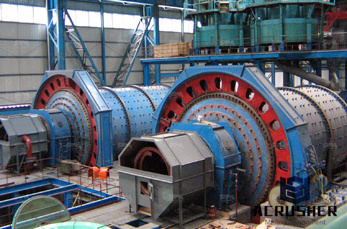

Removing the goldbearing rock from the ground is just the first step. To isolate pure gold, mining companies use a complex extraction process. The first step in this process is breaking down large chunks of rock into smaller pieces. At a mill, large machines known as crushers reduce the ore to pieces no larger than road gravel.

Jan 23, 2012· As you can see, the process of taking metal ore from the earth and converting it to gold bullion is quite extensive and requires a lot frontend investment and time. In the end though, we get these shiny coins and bars to enjoy. Gold miners too take special care to make the impact of mining for gold as light as possible.

Gold extraction and recovery processes semantic scholar. available for the extraction of gold metal from its ores. amongst these methods, cyanidation is the most common method used in the leaching of gold from the ore. this process involves the dissolution of gold containing ores in dilute cyanide solution in the presence of lime and oxygen.

The process works best when the ore is crushed to small pieces before roasting. Additives, such as common rock salt are often added to the mix before it is heated to enhance the reaction of the sulfides. ..., the extraction of the gold or silver from the ore is not especially difficult. Treatment of the roasted ores was done by normal methods ...

Apr 18, 2017· New gold extraction method both cheaper and faster Researchers have developed technology that can bring down the cost of extracting gold from oxidised copper ores. The new method uses ammoniacyanide leaching to extract gold and is a much faster process.

Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore. Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding .

Sulfide ores, and pyrites in particular, have caused and continue to cause difficulty in recovering the gold values from these ores. In most instances, visible gold can not be seen under microscopic examination of pyrite gold ores. However, if the ore is ground to 200 mesh, most times, a few specs of gold can be visibly seen under microscopic ...

Figure 4 CIL/ CIP Process Flow Schematic. Both CIP and CIL are continuous processes, where activated carbon is added to the ore/ water pulp. The first step in gold extraction is leaching the gold which turns gold in solid form to liquid with cyanide in the presence of oxygen.

Gold extraction Gold ore processing •The most commonly used process for gold extraction. •Used to extract gold from lowgrade ore. •Gold is oxidised to a watersoluble aurocyanide metallic complex Au(CN) 2. •In this dissolution process, the milled ore is agitated with dilute alkaline cyanide solution, and air is introduced: Gold ...

"To extract three grams of gold from ore, you need one tonne of rock. We are not yet viable on a big scale like that," he said, adding that to that end they are currently searching for industry ...

Cyanide process is also called as Macarthurforest Process. It is the process of extracting gold or silver from the ores by dissolving in a dilute solution of potassium cyanide or sodium cyanide. This process was introduced in the year 1887 by the Scottish chemists naming Robert W. Forrest, John S. MacArthur, and William Forrest.

Here is a discussion of the procedures to crush Quartz or other minerals and extract the gold from these rich ores. For really large chunks of material, it may be necessary to .

Extraction of Silver by cyanide process and its uses. Silver also occurs both in combined state as well as in free state. The important ores of silver are: Argentite (Ag 2 S), Copper silver glance, Horn silver, Ruby silver. The silver ores are found along with gold ores in some parts of India.

The process of extracting metal ores buried deep underground is called Mining. The metal ores are found in the earth''s crust in varying abundance. The extraction of metals from ores is what allows us to use the minerals in the ground! The ores are very different from the finished metals that we see in buildings and bridges.

Amalgamation is one of the oldest methods of extracting gold from its ores. The amalgamation of gold possibly dates from Roman times. The extraction of silver by amalgamation is generally attributed to the Spanish in Latin America in the late sixteenth century even though Biringuccio describes the fundamental principles of the "patio process ...

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

Each process relies on the initial grinding of the gold ore, and more than one process may be used on the same batch of gold ore. Mining 1 In lode or vein deposits, the gold is mixed with another mineral, often quartz, in a vein that has filled a split in the surrounding rocks.

WhatsApp)

WhatsApp)