Reducing Grinding Energy and Cost Magnetite Iron Ore ...

There is significant case study published regarding energy savings and cost efficiencies of the comminution process due to HPGR. Energy savings ranging from 10 to .

WhatsApp)

WhatsApp)

There is significant case study published regarding energy savings and cost efficiencies of the comminution process due to HPGR. Energy savings ranging from 10 to .

The Cretaceous plant at the Hill Annex mine of the Jones Laughlin Steel Corp. was designed with a wet autogenous mill for grinding low grade iron ore so that it could be concentrated by spirals and flotation cells. The plant, on the west end of the Minnesota''s Mesabi Range, went into operation in June 1961, and preliminary operating and metallurgical information describing the performance ...

Oct 03, 2018· Due to flotation upgrading we now have 67% concentrate, and this brings the product''s quality to a new level. I mean pellets with 65% iron content," says the CTO of Poltava Mining. Introduction of the new iron ore concentration technologies entails upgrading the next downstream process, namely filtration.

Drakelands Mine, formerly known as,tungsten and china clay was,The DMS concentrate is fed into a regrind ball mill which operates in closed circuit with a 450 . regrind ball mills price Grinding Mill China specification regrind mill for iron ore A regrind ball mill is a type of ball mill .

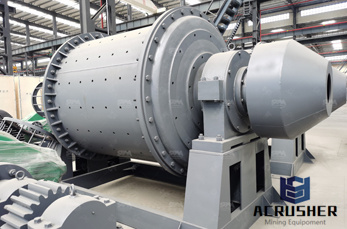

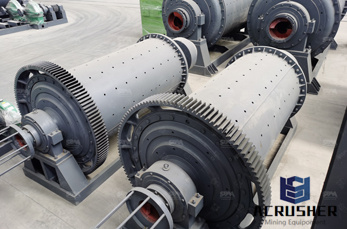

ball mill for grinding iron ore, ball mill for grinding . offers 2,440 ball mill for grinding iron ore products. About 79% of these are Mine Mill, 1% are Grinding Equipment. A wide variety of ball mill for grinding iron ore options are available to you, such as condition, local service location, and applicable industries. Get Price

Iron Ore Conference Perth, WA 3 ABSTRACT Ernest Henry Mining (EHM) is situated 38 km northeast of Cloncurry in the Mount Isa – Cloncurry mineral district of NorthWest Queensland. The EHM ore body is an iron oxide copper gold deposit with an average grade of 1 %copper, g/tonne gold and 23%

Today, the company produces 60% of iron ore using natural moisture processing. By 2024, from the production using wet processing (30%), 16% will have filtered and drystacked tailings, with only 14% continuing to use the conventional method with wet concentration and tailings disposal in dams or deactivated extraction sites.

Through the introduction, digestion and innovation, thus makes the company''s product always keeping the international advanced level. New type crusher (crawler type, rubber type mobile crushing plant), sandmaking machine (5X sandmaking machine), grinding mill (LM vertical mill, MTW European type grinding mill) etc, wins the high reputation in the overseas market and owns absolute market ...

Most iron and steel in the United States is now made from iron and steel scrap, rather than iron ore. The United States is also a major importer of iron and steel, as well as iron and steel products. Employment as of 2014 was 149,000 people employed in iron and steel mills, and 69,000 in foundries.

Concentrate: ore that has been refined to remove the bulk of waste materials. Handling iron ore in bulk carrier Most iron ore is carried in Capesize ships, larger than 80,000 tonnes deadweight, although ships of this category are often much bigger and are generally in the .

Mineral Processing Concentrator Gravity Gold Spiral Chute Separator. US 1000 10000 .. 5LL 900 Spiral Chute gravity concentration for gold prospecting equipment . 2012 A number of mineral flotation sulfide, soluble salt and iron ore china iron ore processing ball mill,iron ore concentration plants china iron ore processing ball . Buy Now

ball mill for grinding iron ore, ball mill for grinding . offers 2,440 ball mill for grinding iron ore products. About 79% of these are Mine Mill, 1% are Grinding Equipment. A wide variety of ball mill for grinding iron ore options are available to you, such as condition, local service location, and applicable industries. Get Price

Iron ore sinter is produced by lumping and sintering the iron ore concentrate, sintering ore, coal dust, and flux additives (the agglomeration process). In the iron and steel industry, iron ore sinter is used as the primary iron ore feedstock for ironmaking in blast furnaces.

At the plant site an additional stage of crushing occurs before the ore is sent to the concentrator. The concentrator utilizes rod mills and magnetic separation to produce a magnetite concentrate, which is delivered to the pellet plant. From the site, pellets are transported by CN rail to a ship loading port at Duluth, Minnesota, operated by CN.

Iron ore Wikipedia. Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel—98% of the mined iron ore is used to make steel. Indeed, it has been argued that iron ore is "more integral to the global economy than any other commodity, except perhaps oil ". coarse aggregate mining india[mining plant]

high efficiency and energy saving gold ore concentrating mill. china factory price 8240 t/h wet magnetic separator,wet products features: high efficiency, huge processing capacity, smooth operation bottom of drum, and the magnetic ores fall into concentrate tank after reaching a certain height, while the non magnetic ores will energy saving gold machine.

The company New Steel has developed a revolutionary new process for iron ore concentration for which New Steel has been awarded with the internationally highly esteemed Platts Global Metals Award for Innovation 2015. This new processing route utilises Loesche grinding technology in the form of its Ore Grinding Plant (OGP) "and is considered ...

Ironrich powder is then mixed with water and clay into a slurry that is shaped into pellets, heated, dried, and shipped to steel mills. The pulverized waste rock—known as tailings —is loaded into waterfilled retention basins, where it eventually settles to the bottom and reenters the rock cycle.

Each primary mill contains several 4" steel balls that grind the ore as the mills turn. When the ore is reduced to 3/4" or less, it moves out of the mill in a slurry solution. The mill ... A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a ...

Iron Ore Testing Laboratory Mineral Testing Labs Mitra . Iron ore is the raw material used to make pig iron which is one of the main raw materials to make steel. 98 of the mined iron ore is used to make steel. Iron Ore is the fourth most abundant element in the Earth s crust. MILL SCALE. Get Price; China March iron ore imports dip sees firm ...

Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc. The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Mill, Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and Dryer.

progress. Production of iron nuggets, essentially pig iron, has begun at one operation in the Mesabi Range. Nuggets can supplant the need for blast furnaces at steel mills. Also on the Mesabi Range, a fully integrated minetosteel mill is under construction and will be the first self contained ore .

Jul 26, 2018· At the new concentrating mill, iron ore was fed by a conveyor belt to highintensity wet magnetic separators. 4 The metal was then passed over several screens to separate the rock into different sizes. While the tailings were discharged to a waste tailings area, other types of rock were fed into concrete silos and crushed for use as a roadway ...

Iron ore is a nonfungible commodity, and its quality varies. To help facilitate price adjustment for differences between expected and delivered product specifications, PRAs have developed valueinuse (VIU) indices for the key priceaffecting chemical components of iron ore iron.

WhatsApp)

WhatsApp)