Pulverized Coal Feeding Handling System YouTube

Feb 08, 2018· Pulverized coal is the most widely used fuel in the steel sector. Watch how its selection, pulverization and quality check using a bomb calorimeter is key to an energy efficient system.

WhatsApp)

WhatsApp)

Feb 08, 2018· Pulverized coal is the most widely used fuel in the steel sector. Watch how its selection, pulverization and quality check using a bomb calorimeter is key to an energy efficient system.

Jul 31, 2011· Pulverized coal mills with throats that are too wide will have corresponding low throat velocity in the mill grinding zone that contributes to excessive .

Pulverised bituminous coal (pulverisedfuel) is burned at some electricity power stations, producing pulverisedfuel ash, about 20–25 per cent of which becomes fused together like clinker and is known as ''furnacebottom ash'' (section ) whilst the remaining 75–80 per cent is a fine pfa dust or ''fly ash'' collected from the ...

Steel Rolling Mill Machinery Providing you the best range of pulverized fuel firing system, cyclone dust collector, dust collector, coal feeding plant, steel rolling mill and trima cyclone with effective .

The two methods used to feed the pulverized fuel to the combustion chamber of the power plant: 1. Unit System 2. Central or Bin System. In unit system, each burner of the plant in fired by one or more unit pulverizers connected to the burners, while in central system, the fuel is pulverized in the central plant and then distributed to each furnace with the help of high pressurized air currents ...

Proven and customized technology and parts for mills of varied OEMs, fuels, wear materials (low chrome, high chrome, ceramic) Xwin ® technology that extends running life of tires and segments, increases time between maintenance cycles, reduces OM costs, lengthens consistency of grinding profiles and reduces power consumption

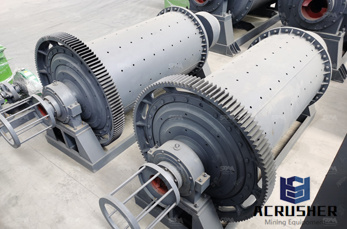

Pulverised fuel grinding mills Pulverised fuel grinding mills Pulverizer Wikipedia A pulverizer or grinder is a mechanical device for the grinding of many different types of materials For example a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel .

Pulverizers 101: Part I POWER Magazine. Aug 1, 2011 ... Every coal pulverizer is designed with a particular fuel grinding ... What is your first step after experiencing a burner fire, mill fire, mill puff, or a mill explosion? ... 70% of the pulverizers used in modern pulverized coal plants.

Feb 09, 2018· Pulverized coal is the most widely used fuel in the steel sector. Watch how its selection, pulverization and quality check using a bomb calorimeter is key to an energy efficient system.

Supply and delivery of Mill Grinding for use with pulverised fuel tube mills for a period of 8 months : MPGXC005548 : 18 : 98 : Participants . Participant name Participants contact details • Grinding Media South Africa BT Projects • Grinding Media South Africa BT Projects ...

Pulverised fuel grinding mills. Pulverised fuel grinding mills pulverised fuel grinding mills pulverizer wikipedia a pulverizer or grinder is a mechanical device for the grinding of many different types of materials for example a pulverizer mill is used to pulverize coal for combustion.

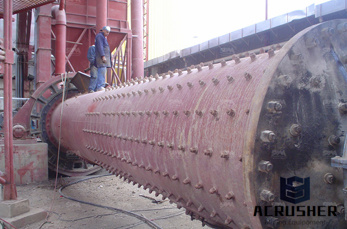

Pulverised Fuel Mill. Bratan engineering is a specialist supplier replacement parts, consumables and components used in Pulverised Fuel Mills (PF Mills) and boiler sections of coalfired power stations. We supply standard and customised precision manufactured. components.

pulverised fuel grinding mills MC pulverised fuel grinding mills. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

Pulverised Fuel Grinding Mills. Pulverised fuel grinding mills Pulverised fuel grinding mills Pulverizer Wikipedia A pulverizer or grinder is a mechanical device for the grinding of many different types of materials For example a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel . Read More

pulverised fuel grinding mills MC pulverised fuel grinding mills. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding .

Pulverised fuel ash pulverised fuel ash pfa is a byproduct of pulverised fuel typically coal fired power stations the fuel is pulverised into a fine powder mixed with heated air and burned approximately 18 of the fuel forms fine glass spheres the lighte Manufacturer In Pulverized Fuel Pipe For Coal Mill In .

Mill power consumption in blends tends to follow the power consumption for the harder coal (Conroy et al., 1989). Bailey et al. (1996) related grinding energy, HGI, and the mesh size at which 80% of the pulverized coal passes (P 80) for lithotypes from high and

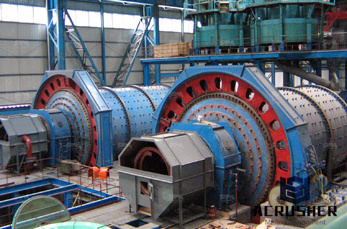

mills. Each mill can provide 65 tons per hour of pulverised coal to the boiler, or a total of 195 tons per hour, per boiler. Because the balltube mills have outlets at each end, with a classifier on each outlet, two sample points were needed on each mill. For enhanced reliability, a redundant configuration was chosen with two sample points on each

2018 new coal gangue mill ym200 coal roller mill test standards cost coal grinding mill difference between tube mill and ball mill coal pulverized raymond mill mps190hp 11 coal mill price china iran coal mill for sale vertical millchina Dynamic Rotary Throat In 10e10 Coal Mill best coal crusher mill ball mill pulverizers coal china . Chat Online

images of pulverised of grinding limestone. pulverised fuel grinding mills faldigroup. pulverised fuel wet ball mill igogreenfoundation. pulverised fuel mill explosions Grinding Mill China. Coal dust,the free encyclopedia. Pulverised coal is a significant dust explosion hazard, as large quantities are suspended in air for transfer from the

A solid fuel pulverizer especially useful in a system for pulverizing and burning solid fuel, such as coal or other fossil fuel, that is characterized by a possible turndown ratio of up to at least fifteen to one. The pulverizer is capable of both impact and autogenous pulverizing of the fuel so that about 80% will be no more than 40 microns in size and includes a series of impellers mounted ...

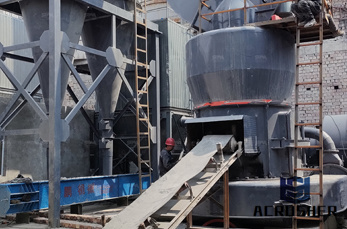

The finished pulverized coal is moved through the pulverizedcoal ducts to the boiler burners. The output of modern hammer mills reaches 70 t/h (lignite) and 5060 t/h (coal). The modern hammer mill is one of the most costeffective milling devices designed for coal grinding. Click Here

Introduction. This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes.. The 3D model in the saVRee database represents a vertical grinding bowl grinding mill types include the ball tube mill, hammer mill, ball and race mill, and, roll and ring mill.

In addition there is heated combustion air fed to the mill to transport the pulverised coal, and the secondary air supply as shown in Fig. 4. Grinding. The grinding function reduces coal fed into the mill into a dust with particles of the size required for combustion. There are two main types of mill in common use: the spindle type and the drum ...

WhatsApp)

WhatsApp)